Krones Can Filling Line

Sold

Krones Can Filling Line

Description

Characteristics:

Capacity:

• 0,15l, 0,25l 65.000 cans per hour

• 0,33l 50.000 cans per hour

• 0,5l 37.000 cans per hour

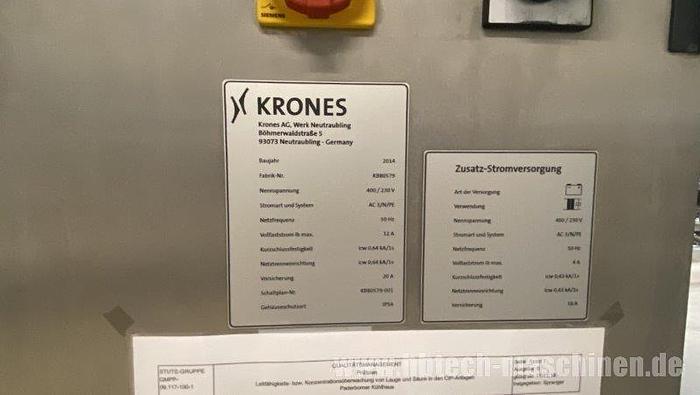

Year of construction 2014

Filling and packaging technology

1. Container pusher PRESSANT UNIVERSAL 1A

2. Empty can inspector CANTRONIC 709 D

3. Can filling machine VOLUMETIC VODM-C2.160-72-94

4. Control device CHECKMAT731 FM

5. Foam cleaning

6. One-way packaging machine VARIOPAC PRO TFS-9

7. Pallet loader MODULPAL 1ADR

8. Pasteur LINAFLEX LC23.6-523-31

9. Container transport SYNCO S

10. Control device CHECKMAT 731 FM-X

11. Container transport MULTICO S

12. Pallet transport PALCO S - area loader

13. Pallet transport PALCO S - Pusher area

Process technology

14. Beverage processing technology CONTIFLOW 30 / 6.

15. CIP system VARIOCLEAN AUT-5,000L, 30 M3/H

Information technology and communication technology

16. Network/Hardware Technology

17. LDS (Production Data Collection)

18. Plant Visualization

Third-party machines

19. Can lid feeder

20. Can sealer

21. Foil wrapper

22. Drying systems FM LNL

23. Container coding systems

24. Pallet labeller

25. Electro-energy distributor

Processing program

150ml optional

250 ml standard can:

a) in a tray of 15 with and without foil

on Euro and Düsseldorf pallets

b) in a tray of 24 with and without foil

on Euro and Düsseldorf pallets

c) in a tray of 18 with and without foil_

on Euro and Düsseldorf pallets

330 ml standard can:

a) in a tray of 24 with and without foil

on Euro and Düsseldorf pallets

b) in a tray of 18 with and without foil

on Euro and Düsseldorf pallets

330ml sleek can:

a) in a tray of 24 with and without foil

on Euro and Düsseldorf pallets

b) in a tray of 18 with and without foil

on Euro and Düsseldorf pallets

355 ml sleek can:

a) in a tray of 12 with and without foil

on Euro and Düsseldorf pallets

b) in a tray of 24 with and without foil

on Euro and Düsseldorf pallets

c) in a tray of 18 with and without foil

on Euro and Düsseldorf pallets

500 ml standard can:

a) in a tray of 24 with and without foil

on Euro and Düsseldorf pallets

b) in a tray of 18 with and without foil

on Euro and Düsseldorf pallets

568ml optional

• System efficiency 90% according to DIN 8782, based on the reference

• CO2 content 0 - 8 g

• Mixer control accuracy +/-0.01°Brix, CO2 +/-0.04 g/l

• Mixer control range up to 9 g/I

• Pasteurizing for products 0 - 5 g CO2/Itr. and pH < 4.5, according to attached PU schemes

• Pulp 0.4 x 0.4 x 0.4 mm, max. pulp content 10%

• Fibers max. 1 x 5 mm max. fiber content 5%

• Filling temperature 20°C, with cooling (ice water) 14°C

• pH < 4.5, Highly acidic for CSD

• Foaming behavior, non-foaming or only slightly foaming products

• Viscosity <500 mPas (Newtonian fluids)

• Reduced performance due to highly foaming products and/or increased viscosity possible

• Filling accuracy according to Gaussian curve, for cans <501 ml sigma 1 = 1.1 ml

• Conductivity < 40uS/cm

• Maximum permitted chloride content for surfaces in contact with product <80 mg/l for material AISI/VZA

• Diameter min. 40 mm / max. 70 mm

• Height min. 78 mm / max. 180 mm

• Cover diameter 202 and 200

• Changeover time for the lid diameter on the Ferrum with quick change > 2.5 h

• Conditions deviating from the above specifications must be verified by tests before processing is released

Specifications

| Condition | Used |

| • Products | Energy drinks, non-alcoholic drinks, juices |

| • Reference | Output 50,000 cans / h for the 330 ml can |